- Wedge welded screen wire mesh screen panel Related

- Wedge welded screen wire mesh screen panel News

- Wedge welded screen wire mesh screen panel Tips

Wedge welded screen wire mesh screen panel

|

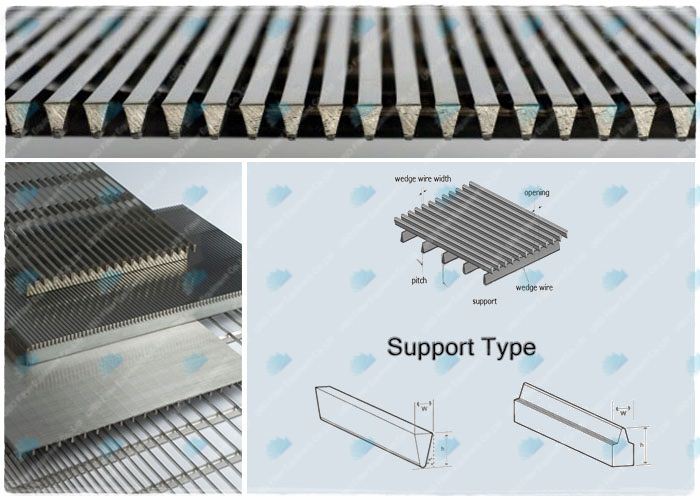

wedge welded screen wire mesh screen panel is in flat, curved or cylindrical panels made of looped, round and/or wedge shaped woven wires for precise openings.It is supplied in stainless steel and other special steel metals and alloy metal screens, mainly used on dewatering equipment.Wedge wire screen is made with certain size of woven wire cloth as screen fabrics, then framed with stainless steel or coated carbon steel plates. offering great strenght. precision ,long service life.

1) It has high mechanical strength, can bear large pressure drop.

2) It has equal slots for filtering, can form equally distributed filter cake, easy to clean for reuse.

3) The wedge type slot can improve backflushing and regeneration performance.

4) It has resistance to pressure, temperature, aging, corrosion, can be applied for different kinds of fluid.

1) Non-clogging:wedge wires are often produced in a variety of sizes and depending on the head width and profile depth, the v-shape creates slots that inwardly enlarges, minimizing and avoiding clogs caused by solid particles.

2) Quick and Easy Maintenance: cleaning of the screen via mechanical scraping or back flushing is easy because of its surface screen.

3) Accurate and Precise Slot Sizes: as screens are easily customized, it is easier to create precise slot sizes that will meet the customer's specifications.

4) Extended Usage; because of the welded structure of the screen, it is capable of self-supporting itself resulting in a durable and stronger screen that would last longer than other materials. Low Cost. The structured pattern provides an effective flow resulting in high yield and lower pressure drop.

5) Resistance to Chemical corrosion: wedge wire screen are made of stainless steel material, resulting in corrosion resistance from chemicals and high temperatures, making these the excellent choice as compared to other screen materials.

The wedge welded screen wire mesh screen panel can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filters.